Maintenance and repairs of stationary and suspended rail welding machines, supply of spare parts

Research and Production Company "WELDING TECHNOLOGIES", LLC provides set of operations to maintain the operability of rail-welding equipment, including warranty and post-warranty maintenance, periodic repairs, manufacture and supply of spare parts for different types of rail-welding equipment.

The list of spare parts exceeds 1300 items and consists of the following groups:

- Welding head: housing parts, guides, levers, alignment mechanisms, deburring sets, curtains;

- Secondary circuit: welding transformers, current leads, flexible buses, electrodes;

- Hydraulic Installation: hydraulic devices, sensors, fittings, HP-hoses;

- Electrical Installation;

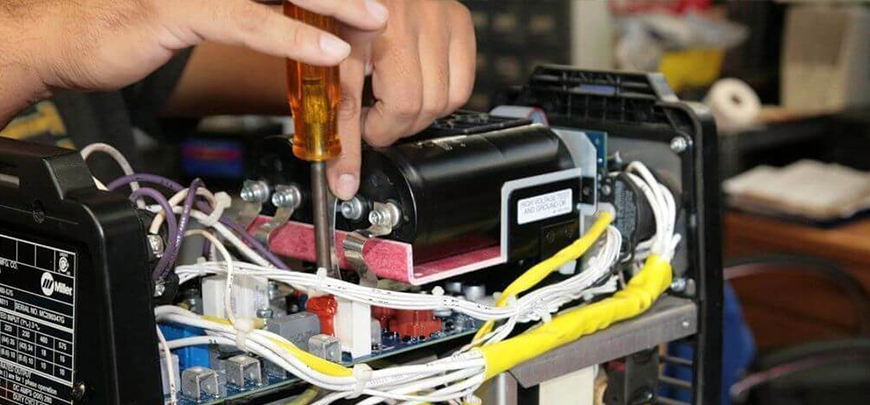

- Electrical Equipment Unit;

- Control system and software;

- Hydraulic drive station: hydraulic cylinders, hydraulic devices, sensors, oil pumps.

The warranty period for supplied spare parts is set in technical documentation of the Manufacturer.

"WELDING TECHNOLOGIES" Company , LLC provides the following types and frequency of maintenance service and repair works of rail-welding equipment:

- Technical Control Inspection when necessary.

- Current Repair, annually.

- Average Repair once in two years.

- Overhaul No.1 after the set service time.

- Overhaul No. 2 after the set service time.

- Unscheduled Repair in case of emergency failure or malfunction of equipment.

"WELDING TECHNOLOGIES" Company, LLC provides appropriate warranty periods for all repairs.