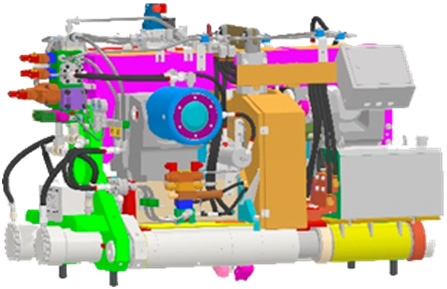

The rail-welding machines MSR 120.02 U1 / MSP-60 U1 are designed for the flash butt welding of R50 and R65 rails directly in-track by way of continuous or pulsatile flashing, with deburring immediately after welding. The machine is part of the MSK-01ST, MRK-01ST, and PRSM mobile rail-welding systems, and is also used at rail-welding facilities for welding substandard rails.

The control system of the MSR-120.02 U1 / MSP-60 U1 machines is a proprietary system developed by the Research and Production Company "Welding Technologies” LLC. It supplies control signals for actuators, processes sensor data in manual (adjustment) mode or semi-automatic mode, and creates technological cycles according to the welding parameters set by the operator. Welding parameters are set using the panel PC mounted on the control cabinet door, or using a laptop. Actuators are directly controlled from the operator control panel located in the welding machine.

The control system can be used in the following operating modes:

- Main semi-automatic mode (ensures operation of the equipment in a cycle mode, i.e. with confirmation of the execution of successive cycles by the operator from the control panel) with automatic positioning the welded ends of the rails relative to each other.

- Manual mode when execution of all actions by the actuators is based on the signals given by the operator from the control panel.

- Test mode.

The control system is built using the Omron NX series industrial controller. The MSR-120.02U1 / MSP-60 U1 control system interface provides:

- Set up and monitoring of the quality-relevant process parameters of the welded joints

- Actuators status monitoring

- Real-time updates on the welding process progress

- Accumulating and storage of welding process data for each joint

- Issue of certificates for each welded joint

- Creation of certificates for welded joints with the following information: date, time, rail number, joint number, welding result (VALID/INVALID), main process parameters of the machine during the cycle.

- Keeping a log of welded joints certificates

- Self-monitoring and self-diagnostics

MSR-120.02U1 / MSP-60 U1 suspended rail-welding machines specifications

|

Parameter |

MSR-120.022 |

MSP-60 |

|

Operating supply voltage at 50 Hz, V |

380 |

380 |

|

Apparent power at 50% duty cycle, kVA min. |

240 |

240 |

|

Max. secondary current, kA min. |

72 |

72 |

|

Sustained secondary current, kA |

21,4 |

21,4 |

|

Nominal upset force, t |

120 |

60 |

|

Max. gripping pressure, kN |

2900 |

1600 |

|

Burn-off speed adjustment range mm / s |

0,2-2 |

0,2-2 |

|

Max. welding time for R-65 rail, sec |

240 |

240 |

|

Dimensions, mm max. |

||

|

- welding machine |

1876х1170х1130 |

1790х1145х1220 |

|

- hydraulic drive unit |

1021х662х1630 |

1021х662х1630 |

|

- electrical equipment |

1090х550х1670 |

1090х550х1670 |

|

Weight, kg max. |

||

|

- welding machine |

3 750 |

3100 |

|

- hydraulic drive unit |

1 000 |

1000 |

|

- electrical equipment |

650 |

650 |