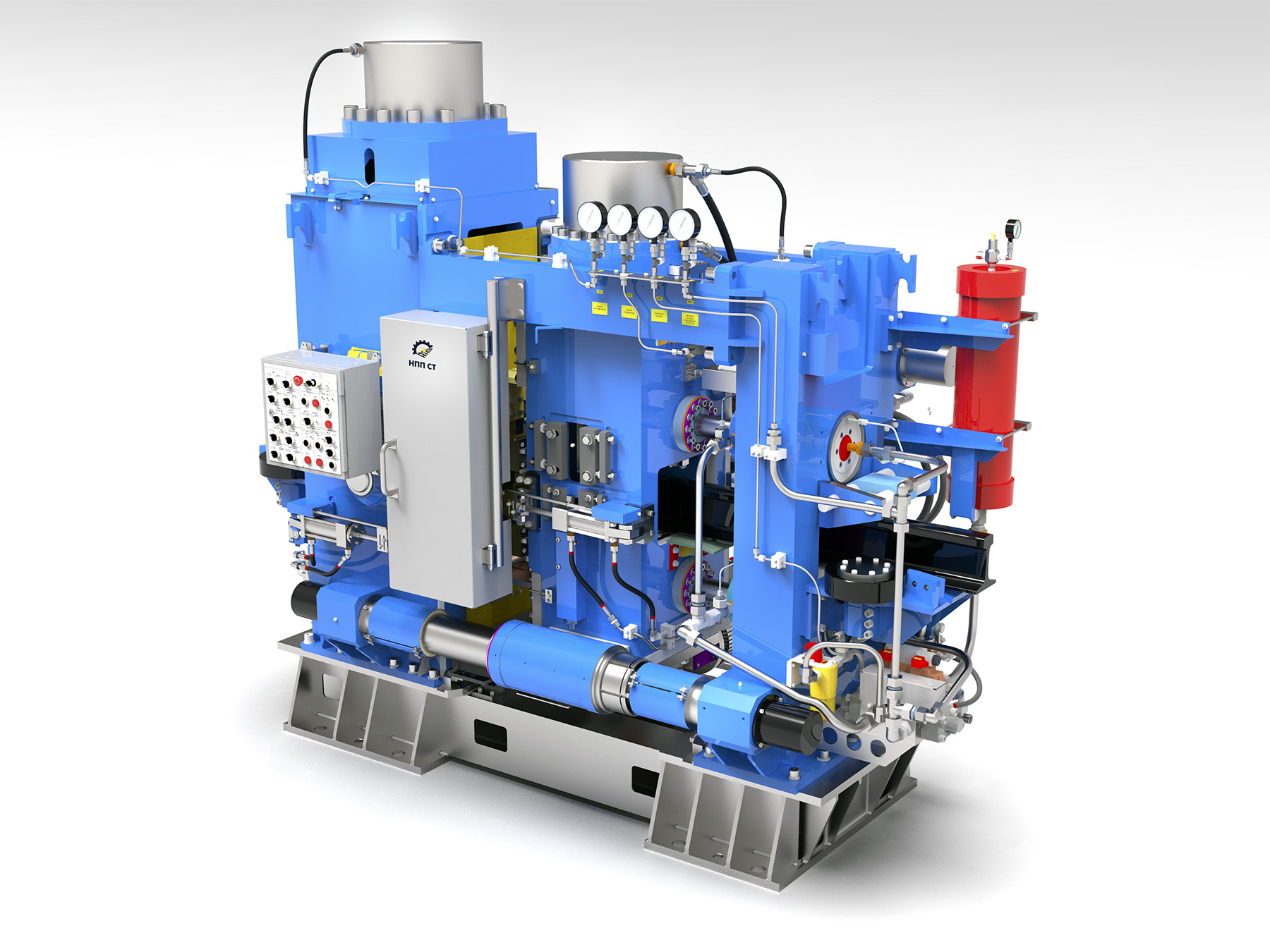

The rail-welding machine MSU-84 UHL4 is designed for the stationary flash butt welding of R50, R65, and R75 rails by way of continuous or pulsatile flashing, with deburring immediately after welding. The machine is used as part of a technological line for welding long rails at a stationary rail welding facility.

The control system of the MSU-84 UHL4 machine is a proprietary system developed by the Research and Production Company "Welding Technologies” LLC. It supplies control signals for actuators, processes sensor data in manual (adjustment) mode or semi-automatic mode, and creates technological cycles according to the welding parameters set by the operator.

Welding parameters are set using the panel PC mounted on the control cabinet door, or using a laptop. Actuators are directly controlled from the operator control panel located in the welding machine.

The control system can be used in the following operating modes:

- Main semi-automatic mode (ensures operation of the equipment in a cycle mode, i.e. with confirmation of the execution of successive cycles by the operator from the control panel) with automatic positioning of the welded ends of the rails relative to each other.

- Manual mode when execution of all actions by the actuators is based on the signals given by the operator from the control panel.

- Test mode.

The control system is built using the Omron NX series industrial controller. The MSU-84 UHL 4 control system interface provides:

- Set up and monitoring of the quality-relevant process parameters of the welded joints;

- Actuators status monitoring;

- Real-time updates on the welding process progress;

- Accumulation and storage of welding process data for each joint;

- Issue of certificates for each welded joint;

- Creation of certificates for welded joints with the following information: date, time, rail number, joint number, welding result (VALID/INVALID), main process parameters of the machine during the cycle;

- Keeping a log of welded joints certificates;

- Self-monitoring and self-diagnostics.

MSU-84 UHL4 technical specifications

Parameter |

Standard value |

|

Three-phase AC supply voltage, V 380 |

380 |

|

Supply frequency, Hz |

50 |

|

Max. short circuit power, kVA 871 |

871 |

|

Max. secondary current, kA min. 110 |

110 |

|

Welding transformers power at 50% duty cycle, kVA, at nominal step |

350 |

|

Sustained continuous secondary current, kA |

28 |

|

Welding transformers ratio at regulation steps:

|

48 |

|

Rated upset force, kgf: |

84 000 |

|

Rated gripping force, kgf: 210,000 |

210 000 |

|

Movable housing travel, mm min. |

145 |

|

Clamp travel, mm, min. |

83 |

|

Max upset speed, mm / sec, min. |

30 |

|

Burn-off speed adjustment range:

|

0,2 |

|

Short-term welding productivity R65 rails, joints / h, min. |

15 |

|

Distance between electrodes, mm:

|

200 |

|

Vertical and horizontal adjustment, mm |

±10 |

|

Excess weld metal after deburring, mm |

0,3...1,5 |

|

Max cross-section of welded parts, mm2 |

10 000 |

|

Cooling water consumption at 0.15 MPa (1.5 kgf / cm2), l / min, max. |

60 |

|

Dimensions (length / width / height), mm:

|

3055/1389/2787 1610/655/1965 |

|

Weight, kg:

|

13200 |